Enhancing Manufacturing Efficiency with Injection Molding Services of Jobr Tech

Injection molding services play a crucial role in modern manufacturing by enabling the mass production of high-quality plastic components. This process involves injecting molten material, typically plastic, into a mold cavity. Once cooled and solidified, the mold is opened, and the finished product is ejected. The versatility and cost-effectiveness of injection molding make it an ideal choice for various industries, including automotive, consumer goods, medical devices, and more. Among the leading providers in this field, Jobr Tech stands out for its commitment to excellence, advanced technology, and customer satisfaction.

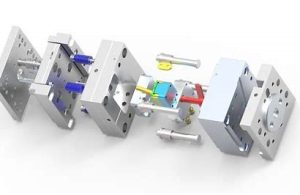

Jobr Tech: High-Quality Custom Injection Molding and Mold Tool Making

The benefits of Jobr Tech’s injection molding services are manifold. Firstly, it specializes in high-quality plastic custom injection molding and mold tool making. Plastic injection molding is the industry’s most common way to manufacture parts, especially when making larger quantities. Jobr Tech have thousands of different types of plastic available for you to choose from for a wide range of mechanical and cosmetic properties.

Advantages of Injection Molding: Repeatability, Surface Quality, and Over-Molding

Additionally, injection molding offers excellent repeatability, ensuring consistent quality across large production runs. Hundreds of thousands of moldings can be produced from a single mold. Your part can have excellent surface quality finishes in a wide range of polishes and textures. Over-molding is available to combine different types of plastic in one piece. It is ideal for lightweight parts that are immune to corrosion.

Jobr Tech’s Injection Molding Services: Material Diversity and Custom Manufacturing for Large Production Runs

Another advantage of injection molding services is their ability to produce parts with a wide range of materials. From commodity plastics to engineering-grade polymers, manufacturers can choose from a vast selection of materials to meet specific requirements such as strength, durability, and chemical resistance. Jobr Tech provides plastic injection molding services for 50 to 100,000+ parts and a wide range of other manufacturing and finishing services to complete your project..

Conclusion

Injection molding services have become an integral part of modern manufacturing, offering numerous advantages such as cost-effectiveness, design flexibility, and material versatility. By partnering with Jobr Tech, manufacturers can revolutionize their production processes, enhance efficiency, and achieve superior results in the competitive market.